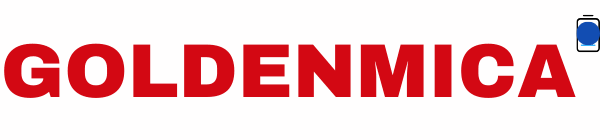

Mica Gaskets – High-Temperature Sealing Solutions

Mica gaskets are specialized sealing components designed to withstand extreme temperatures, making them ideal for demanding industrial applications. They are made from natural or synthetic mica materials, known for their excellent thermal and electrical insulation properties. These gaskets are particularly useful in environments where conventional gasket materials fail due to heat or chemical exposure.

What Are Mica Gaskets?

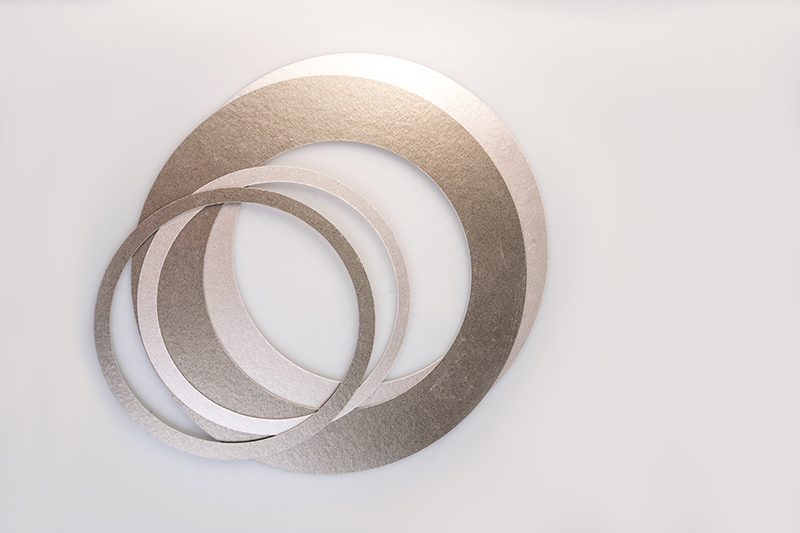

Mica gaskets are manufactured from layers of mica paper—typically phlogopite or muscovite mica—bonded with high-temperature resistant binders such as silicone resin or inorganic materials. Depending on the construction, mica gaskets can be made as:

- Flexible mica sheets

- Rigid mica gaskets

- Metal-reinforced mica gaskets (often with stainless steel or perforated steel core)

These materials provide excellent compression resistance, low thermal conductivity, and outstanding thermal stability, even at temperatures exceeding 1000°C (1832°F).

Key Features of Mica Gaskets

- High Thermal Resistance: Operate effectively in temperatures ranging from 500°C to over 1000°C

- Excellent Chemical Resistance: Resistant to acids, oils, and most industrial fluids

- Electrical Insulation: Ideal for electrical equipment with heat exposure

- Low Emission: Safe for use in sealing applications involving flue gases or exhaust systems

- Customizable: Can be die-cut, water jet cut, or CNC machined to suit specific dimensions

Common Applications

Mica gaskets are widely used in high-temperature sealing applications across various industries:

- Petrochemical and Refinery Equipment

- Heat Exchangers and Boilers

- Electric Furnaces

- Turbines and Exhaust Systems

- Automotive and Aerospace Components

- Heating Elements and Electric Insulation Assemblies

Types of Mica Used in Gaskets

- Phlogopite Mica

- Better thermal resistance

- Gold to copper color

- Withstands up to 1000°C or more

- Muscovite Mica

- Higher dielectric strength

- More stable at lower temperatures (~600–800°C)

The choice of mica type depends on the thermal and electrical requirements of the application.

Why Choose Mica Gaskets?

When it comes to performance in extreme environments, mica gaskets outperform many traditional materials like graphite, PTFE, or fiber gaskets. They provide a safe, durable, and reliable seal even in the harshest operating conditions.

At Goldenmica, we offer custom-cut mica gaskets to meet specific design and application needs. Whether you need flexible or rigid gaskets, with or without reinforcement, our engineering team can help you choose the right solution.

Contact Us for Custom Mica Gasket Solutions

Looking for high-temperature gaskets that won’t fail under pressure?

Get in touch with us today for expert advice and custom mica gasket manufacturing tailored to your industry needs.

- Aerospace

- Aluminium Smelting

- Applications of Mica Products

- Automotive

- Customized Insulator Series

- Electronics

- ESS

- EV Battery Solutions

- Fabricated Mica Parts

- Flexible Mica Sheets

- High Voltage Insulator Series

- Home Appliances

- Low Voltage Insulator Series

- Mica Gaskets

- Mica Pipe

- Mica Plate

- Mica Tubes

- Muscovite Mica Sheets

- News

- News2

- Phlogopite Mica Sheets

- Rigid Mica Sheets

- Steel Industry

- What Are Mica Sheets?

- What Is Mica?

- 未分类