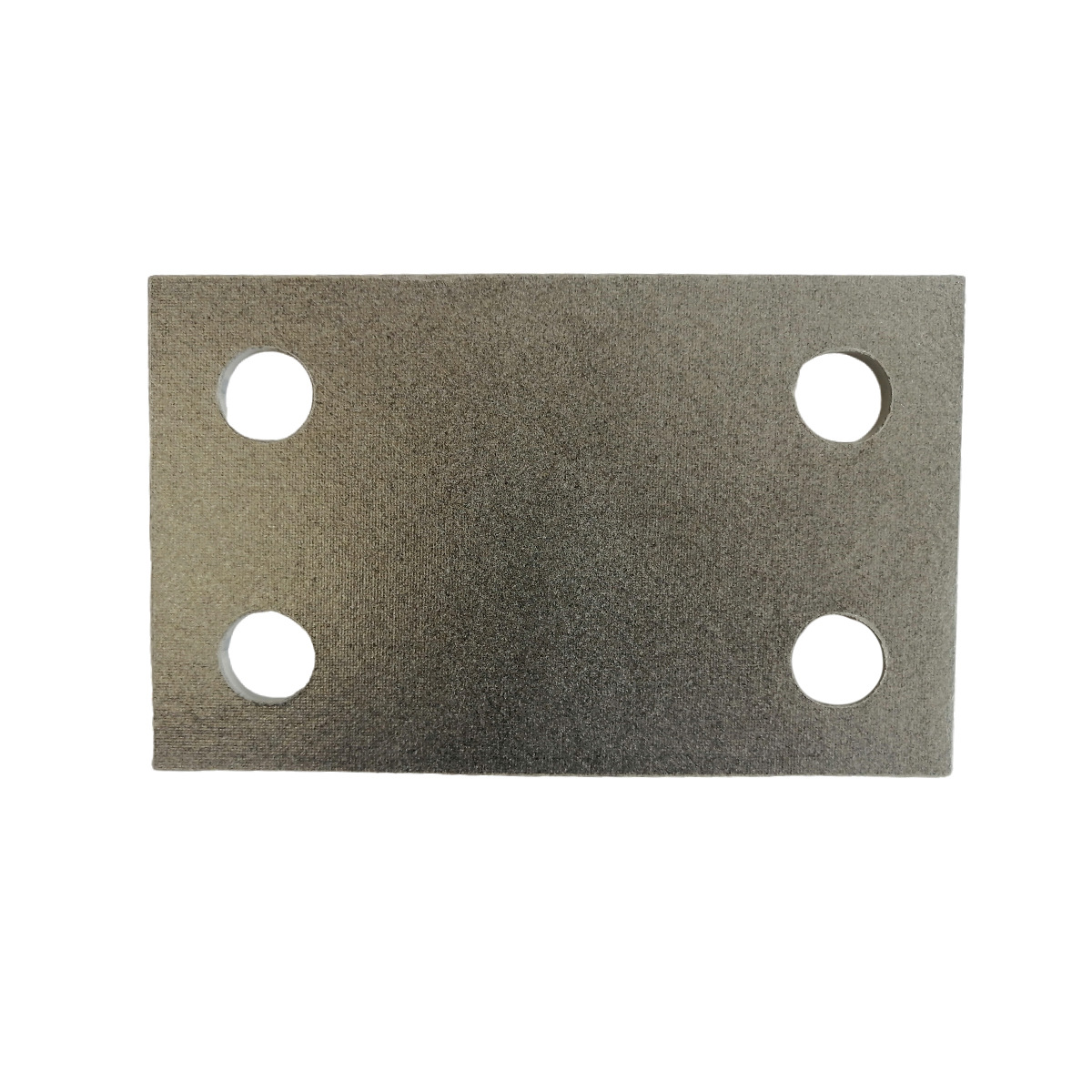

Mica Plate

What is a Mica Plate?

Mica plate is a high-temperature insulating material made from natural mica minerals, processed and bonded into thick, rigid slabs ranging in thickness from 6mm to 100mm. Unlike thinner mica sheets, mica plates are engineered for mechanical durability, structural stability, and extreme thermal resistance.

Mica plates are used in industrial environments where high voltage, high temperature, and mechanical strength are simultaneously required. They are especially critical in foundries, metallurgy, electrical insulation, and heating systems.

How is Mica Plate Manufactured?

The manufacturing process of mica plate involves the lamination of multiple layers of mica paper, which are bonded with heat-resistant resins, typically silicone or epoxy. These layers are then compressed under high pressure and heat to form solid, dense plates.

Production Steps:

Raw Material Selection

Natural mica (muscovite or phlogopite) is mined, cleaned, and graded.

Pulverization & Pulping

Mica is ground into flakes and made into mica paper.

Resin Impregnation

The paper is soaked with high-temperature-resistant resin.

Layering & Lamination

Multiple impregnated sheets are stacked to the required thickness.

Hot Pressing & Curing

The stack is compressed under heat to form a rigid, solid structure.

Cutting & Finishing

Plates are trimmed, machined, and optionally coated or glued.

Types of Mica Plate

Muscovite Mica Plate

Higher dielectric strength

Better chemical resistance

Stable up to 300–500°C

pale color

Phlogopite Mica Plate

Working temperature 700℃,peaks of 1000°C

Superior in thermal shock environments

Brown to golden color

Often preferred in metallurgy and foundry applications

Key Features of Mica Plates

Excellent Thermal Insulation – Withstands temperatures up to 1000°C

High Dielectric Strength – Ideal for high-voltage insulation

Structural Integrity – Rigid and impact-resistant

Fireproof and Flame-retardant – Non-combustible material

Chemically Inert – Resistant to oils, solvents, acids, and alkalis

Machinable – Can be cut, drilled, milled, or custom-shaped

Environmentally Safe – Asbestos-free and non-toxic

Applications of Thick Mica Plates

Applications of Thick Mica Plates

- Electrical Insulation

Transformer partitions

Busbar supports

Generator and motor insulators

Arc shields and slot wedges

- High-Temperature Equipment

Furnace insulation panels

Heating element supports

Protective linings in industrial ovens

- Metallurgy and Foundry

Induction furnace insulation

Steel and aluminum processing gaskets

Thermal barriers in casting molds

- Aerospace and Automotive

Fire-resistant insulation panels

Battery compartment shielding (EVs)

Thermal insulation in aircraft cabins

- Household & Industrial Heating

Toaster oven insulation

Heating block layers

High-temperature gaskets for electric irons and cooktops

Customization Options of Mica Plates

Mica plates can be custom-manufactured according to application needs. Customizations include:

Size and Thickness (up to 100mm)

Pre-cut shapes (round, rectangular, irregular)

Machining – Holes, slots, chamfers, and grooves

Adhesive Backing – Pressure-sensitive or heat-resistant glue

Laminated Layers – With fiberglass or ceramic fabric reinforcement

Conclusion

Mica plates (6mm–100mm) are engineered for demanding industrial conditions that involve extreme heat, high voltage, and mechanical stress. Their unique combination of thermal resistance, electrical insulation, rigidity, and chemical durability makes them an essential material across sectors like metallurgy, power generation, aerospace, and electrical equipment manufacturing.

If you’re looking for a long-lasting, non-flammable insulating solution that performs under the toughest conditions, mica plates are an ideal choice.