Mica Tubes

What is a Mica Tube?

A mica tube is a cylindrical insulating component made from layered mica paper—typically muscovite or phlogopite—bonded with high-temperature resistant resins and wound or molded into a tubular shape. These tubes provide excellent thermal insulation, electrical resistance, and mechanical strength, making them ideal for harsh operating environments that involve high heat and electrical stress.

Mica tubes are widely used in electrical equipment, heating elements, motors, transformers, and high-temperature industrial applications.

How are Mica Tubes Made?

Mica tubes are usually manufactured through spiral winding or molding processes using layers of resin-impregnated mica paper. The layered structure provides dimensional stability and high insulation performance under thermal and electrical stress.

Manufacturing Process::

Mica Paper Preparation

Natural mica is ground into flakes and made into thin, flexible paper sheets.

Resin Impregnation

Mica paper is impregnated with high-temperature binders like silicone or epoxy resin.

Winding or Molding

The mica paper is spirally wound or compression molded into tubes over mandrels to achieve the desired diameter and wall thickness.

Hot Pressing and Curing

Tubes are cured under heat and pressure to solidify the structure.

Finishing

The ends are trimmed, and the tubes are machined to required dimensions. Surface treatments or coatings may be applied upon request.

Types of Mica Tubes

Muscovite Mica Tubes

Higher dielectric strength

Better chemical resistance

Stable up to 300–500°C

Transparent to silver-gray in color

Phlogopite Mica Tubes

Working temperature 700℃,peaks of 1000°C

Ideal for thermal shock applications

Brown or golden in color

Used in metallurgy and furnace insulation

Key Properties

Thermal Resistance: Withstands continuous temperatures of up to 1000°C (phlogopite)

Electrical Insulation: Dielectric strength of 15–20 kV/mm

Non-flammable: Rated Class A for fire safety

Chemical Stability: Resistant to acids, alkalis, oils, and solvents

Mechanical Strength: High rigidity and impact resistance

Machinable: Ends and diameters can be lathed, drilled, or sanded

Applications of Mica Tubes

Mica tubes are trusted components across power electronics, heat-intensive systems, and rotating electrical machines, including:

Electrical Equipment

Insulating sleeves for transformer windings

Internal insulation for motors and generators

Terminal bushings in high-voltage systems

Heating Elements

Housing for ceramic or resistance heating wires

Electric furnaces and coil insulation

Supporting structure for heating rods or tubes

Industrial Applications

Thermal barriers in metallurgy and foundries

Arc shielding in welding equipment

High-voltage cable insulation

Aerospace & Automotive

Fire-resistant tubes in electric propulsion systems

Insulation in battery modules and control units

Customization Options

Mica tubes can be tailored to meet diverse industrial specifications:

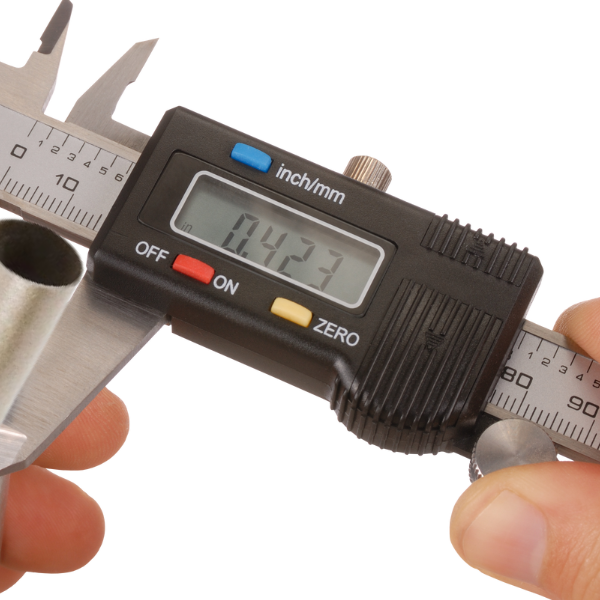

Inner Diameter: From a few millimeters up to 150mm or more

Wall Thickness: Typically 1mm to 10mm (customizable)

Length: From 10mm short tubes to over 1 meter

Machining: Drilled holes, grooves, or slots on the wall

Surface Coating: With ceramic, PTFE, or heat-reflective layers

Adhesive Lining: Heat-resistant or pressure-sensitive adhesives inside or outside the tube

Why Choose Mica Tubes?

High reliability in extreme environments

Durable against both thermal aging and electrical overload

Free from asbestos and environmentally safe

Long service life even under repetitive thermal cycling

Excellent dimensional stability under heat and stress

Mica tubes are a proven solution for thermal and electrical insulation in cylindrical form. With high performance in demanding industrial conditions, these tubes play a vital role in ensuring the safety, efficiency, and reliability of electrical and thermal systems.

Whether used in a transformer winding, a heater assembly, or a furnace coil, mica tubes are the go-to choice for engineers needing heat and dielectric endurance with structural integrity.