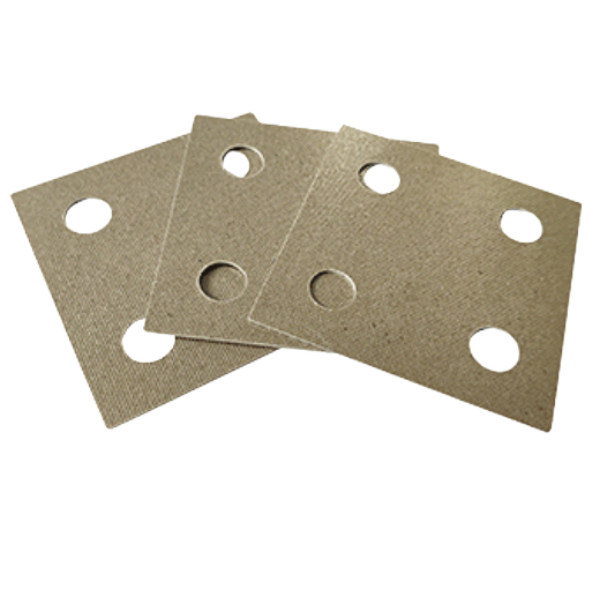

Mica Sheets

Mica sheets are high-performance insulation materials widely used in electrical, thermal, and industrial applications. These sheets are manufactured using mica paper, known for their exceptional thermal and electrical insulating properties. The production of mica sheets involves processing mica paper with a heat-resistant binder, typically silicone resin. This mixture is then compressed under heat and pressure to form solid form.

Types of Mica Sheets: Muscovite and Phlogopite

Mica sheets are mainly classified by the type of mica used in their composition:

- Muscovite Mica : Muscovite is a light-colored mica that offers excellent electrical insulation and moderate heat resistance. It typically withstands temperatures up to around 550°C (1022°F). Due to its stable dielectric properties, muscovite-based mica sheets are ideal for high-voltage electrical insulation, household appliances insulation materials.

- Phlogopite Mica: Phlogopite is a golden brown mica with higher thermal resistance than muscovite. It can endure temperatures up to 750°C (1382°F) or more. This makes phlogopite mica sheets suitable for applications involving continuous high temperatures or sudden thermal shocks, such as in metallurgical or foundry environments.

Structural Classification: Rigid vs. Flexible Mica Sheets

In addition to the type of mica used, mica sheets are also classified by their structural properties into:

- Rigid Mica Sheets: These are solid, dense boards designed for mechanical strength and structural insulation. They are used in applications where form stability and load-bearing capacity are critical, such as in commutators, heating elements, or furnace linings.

- Flexible Mica Sheets These are more pliable and can be cut or formed to fit irregular surfaces. Soft mica boards maintain the same high-temperature resistance as rigid ones but offer superior flexibility. This makes them ideal for wrapping around heating elements, insulating irregular surfaces, or serving as thermal gaskets and barriers.

Why the Classification Matters

The classification into muscovite and phlogopite, as well as rigid and flexible forms, allows engineers and manufacturers to choose the right mica options for specific operating environments:

Material Type determines the sheet’s temperature tolerance and electrical properties.

Structural Type affects how the sheet can be used—whether it needs to be shaped, bent, or hold a load.

Applications of Flexible Mica Sheets

Flexible mica boards are particularly valued in applications that require flexibility without compromising on thermal or dielectric performance. Typical uses include:

- Insulation of heating elements in hair dryers, toasters, and ovens

- Fire-resistant barriers in electrical cabinets and transformers

- Gaskets and thermal seals in industrial furnaces

- Wrapping layers for induction coils and cables in high-temperature environments

- Thermal insulation in aerospace and automotive heat shields

Contact Us

Mica Sheets, whether made from muscovite or phlogopite, and whether rigid or flexible, offer a combination of thermal resistance, electrical insulation, and mechanical adaptability. Understanding these classifications helps in selecting the most suitable material for high-performance and safety-critical applications.

Let us know if you’d like a product catalog or technical datasheet.

Why Choose Our Mica Products?

Goldenmica provide high-quality muscovite and phlogopite mica tailored for demanding industrial applications. Our products ensure:

✔ Superior dielectric performance

✔ Exceptional thermal and mechanical stability

✔ Customizable forms (sheets, films, precision-cut components)

✔ Compliance with international industry standards

Discover how our mica solutions can enhance your industrial processes—contact us today!